| Workpiece material | Carbon Steel(<30HRC) | Pre-hardened steel (HRC30-40) | cast iron | Aluminum alloy | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Outer Diameter(mm) | ap(mm) | ae(mm) | RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

| 4.00 | 6.00 | 1.600 | 9151 | 1098 | 7162 | 859 | 8754 | 1050 | 11937 | 1432 |

| 5.00 | 7.500 | 2.000 | 7321 | 1025 | 5730 | 802 | 7003 | 980 | 9549 | 1337 |

| 6.00 | 9.000 | 2.400 | 6101 | 976 | 4775 | 764 | 5836 | 934 | 7958 | 1273 |

| 8.00 | 12.000 | 3.200 | 4576 | 915 | 3581 | 716 | 4377 | 875 | 5968 | 1194 |

| 10.00 | 15.000 | 4.000 | 3661 | 952 | 2865 | 745 | 3501 | 910 | 4775 | 1241 |

| 12.00 | 18.000 | 4.800 | 3050 | 915 | 2387 | 716 | 2918 | 875 | 3979 | 1194 |

| 16.00 | 24.000 | 6.400 | 2288 | 778 | 1790 | 609 | 2188 | 744 | 2984 | 1015 |

| 20.00 | 30.000 | 8.000 | 1830 | 732 | 1432 | 573 | 1751 | 700 | 2387 | 955 |

| Workpiece material | Carbon Steel(<30HRC) | Pre-hardened steel (HRC30-40) | cast iron | Aluminum alloy | |||||

|---|---|---|---|---|---|---|---|---|---|

| Outer Diameter(mm) | ap(mm) | RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

RPM N (r/min) |

Feed speed Vf (mm/min) |

| 4.00 | 5.000 | 2228 | 434 | 1989 | 388 | 2865 | 559 | 7958 | 1552 |

| 5.00 | 6.250 | 1783 | 134 | 1592 | 119 | 2292 | 172 | 6366 | 477 |

| 6.00 | 7.50 | 1485 | 134 | 1326 | 119 | 1910 | 172 | 5305 | 477 |

| 8.00 | 10.000 | 1114 | 134 | 995 | 119 | 1432 | 172 | 3979 | 477 |

| 10.00 | 12.500 | 891 | 134 | 796 | 119 | 1146 | 172 | 3183 | 477 |

| 12.00 | 15.000 | 743 | 123 | 663 | 109 | 955 | 158 | 2653 | 438 |

| 16.00 | 20.000 | 557 | 109 | 497 | 97 | 716 | 140 | 1989 | 388 |

| 20.00 | 25.000 | 446 | 100 | 398 | 90 | 573 | 129 | 1592 | 358 |

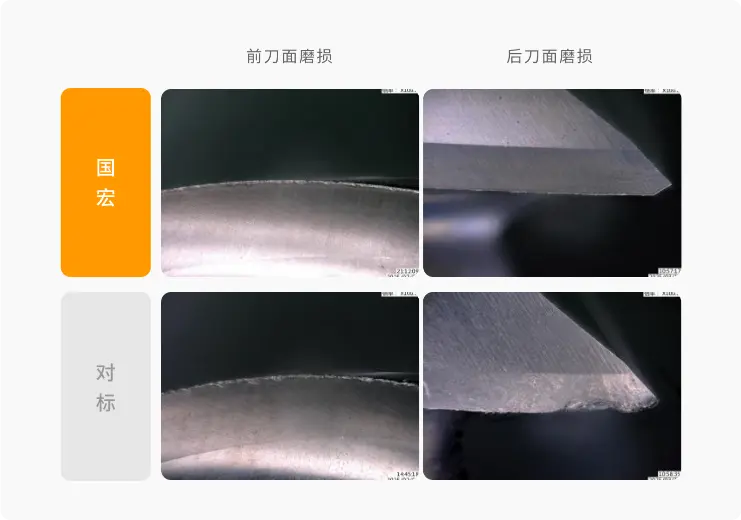

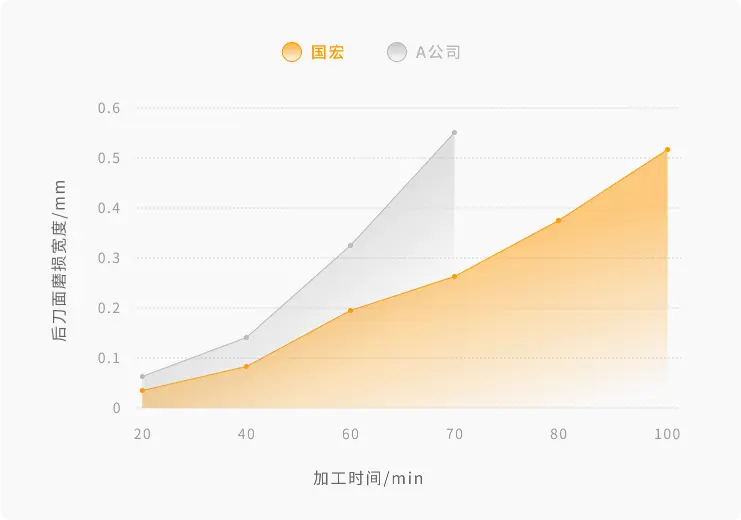

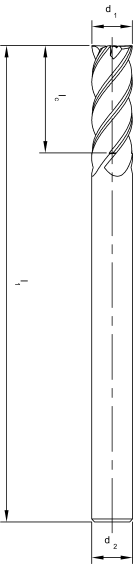

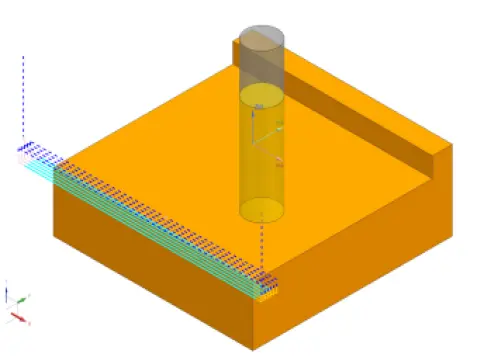

| The tool drawing number | Tool specifications | Test the machine | Rotational speed (N) | Feed (F) | Cutting Width (AP) | Depth of Cut (ae) | Feed per tooth | The material being processed | Cooling method |

|---|---|---|---|---|---|---|---|---|---|

| EHU110-4 | D6 | DMG | 3800rpm | 450mm/min | 2mm | 8mm | 0.03mm/z | Grade4 | Coolant |