R&D Technology

-

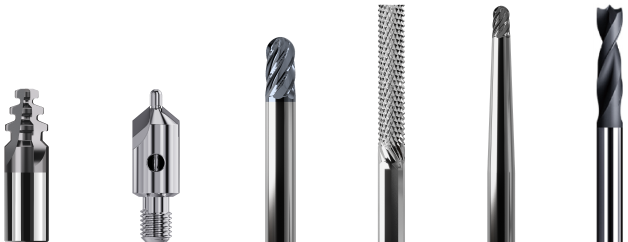

Design technology of tool groove structure

-

Precision grinding technology for tools

-

Cutting edge preparation

-

PVD coating technology

-

CVD coating technology

-

Vacuum brazing connection technology

-

Laser precision machining technology

R&D Process

R&D Equipment

Coating Technology

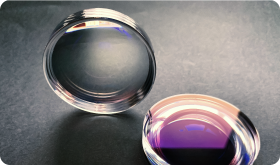

3C titanium alloy coating

-

Operating temperature:<1100°C

-

The coefficient of friction is0.4

-

Roughness0.3

-

Film breaking force>100N

-

Modulus342±10GPa

-

Hardness38±3 GPa

-

Structure:Composite multilayer

-

Color:Dark gray

-

Process:Arc ion plating

-

CompositionAlCrBN/AlCrN

The AlCrN/AlCrBN laminated nanocomposite structure effectively prevents crack propagation, and the multi-layer interface can absorb the energy of crack propagation, thereby improving the toughness and crack resistance of the coating

Due to the increase in cutting line speed, the cutting temperature will increase significantly. We have introduced amorphous BN, which can effectively isolate most of the heat, protect the tool at high temperatures, and thus improve the tool life

Performance comparison

Machining parameters

Vc = 120 m/min

ae = 0.4 mm

F = 0.6 mm/min

20% emulsion | emulsion

ap = 7.58 mm

D6R1×4T×8D×55L

After 60 minutes of continuous high-speed milling of Ti6Al4V titanium alloy, the GHHF-coated tool still has a complete edge topography. Compared with TiB2, AlCrN, TiSiN and ZrN coatings, GHHF has obvious advantages in terms of stability and wear resistance

School-enterprise Cooperation