Engine components

Airframe components

K7R3.5A5d20-20X240S2

K7R3.5A5d20-20X240S2

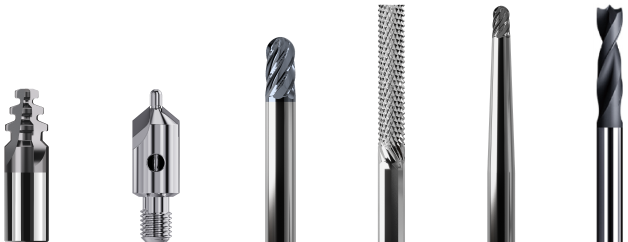

Extreme material adaptability Matching titanium alloy (such as Ti6Al4V), high-temperature alloy (such as Inconel series) and other high-hardness, low thermal conductivity materials processing, the tool needs to have high temperature resistance, anti-adhesion special coating technology; A special coating is used to reduce the cutting temperature and extend the life.

High rigidity material and structural design The solid carbide or ultra-fine grain matrix is adopted, and the taper ball head and vibration damping shank are designed to improve the anti-flutter performance of the tool. Cutting edge geometry optimization, balancing cutting force and chip removal efficiency, suitable for deep cavity machining and complex structure machining capability The blade profile is twisted, the channel is narrow and the deep cavity structure requires the tool to have high rigidity and vibration resistance design, avoid machining deformation, and combine sharp cutting edge and self-chipping design to reduce material work hardening.

High rigidity material and structural design The solid carbide or ultra-fine grain matrix is adopted, and the taper ball head and vibration damping shank are designed to improve the anti-flutter performance of the tool. Cutting edge geometry optimization, balancing cutting force and chip removal efficiency, suitable for deep cavity machining and complex structure machining capability The blade profile is twisted, the channel is narrow and the deep cavity structure requires the tool to have high rigidity and vibration resistance design, avoid machining deformation, and combine sharp cutting edge and self-chipping design to reduce material work hardening.